Fire pumps are fundamental components of any fire protection system, playing a crucial role in stopping or controlling a fire during its early stages. They serve as the primary mechanism for delivering strong and continuous water flow to automatic sprinkler systems or dedicated fire-fighting water networks.

In the event of a fire, fire pumps can make a significant difference in how quickly the fire is contained, ensuring the safety of both people and property. However, having fire pumps installed in a facility is not enough—proper installation and selecting the right type of fire pump are essential to guarantee efficient and reliable performance.

In this article, we explore the importance of proper fire pump installation and how to choose the right fire pump for your facility—powered by ANC, a leading provider of fully integrated fire protection solutions in Saudi Arabia!What Are Fire Pumps and What Are Their Primary Uses?

Fire pumps are specialized devices designed to deliver water or other fire-fighting fluids at high pressure to fire protection systems such as sprinklers or fire hose networks. These pumps are a critical component of any fire protection system, ensuring that the required water supply is available to suppress a fire quickly and effectively when needed.Main Applications of Fire Pumps:

- Fire Suppression: The primary function of fire pumps is to provide sufficient water pressure to extinguish a fire or prevent it from spreading. This is achieved by delivering high-pressure water to sprinklers or fire-fighting pipelines.

- Facility Protection: Fire pumps are used in residential, commercial, and industrial buildings to protect lives and property from fire hazards.

- Emergency Water Supply: Fire pumps ensure a continuous flow of high-pressure water during a fire incident, enhancing the system’s ability to control the fire and minimize resulting damage.

- Integration with Alarm and Automatic Suppression Systems: Fire pumps work in coordination with automatic alarm and suppression systems, activating simultaneously to ensure rapid and effective response during fire emergencies.

What Are the Components of a Fire Pump and How Does It Work?

Fire pumps consist of several essential components that work together to deliver water or other fire-fighting fluids at high pressure to various suppression systems. For the pump to operate effectively, each component must function properly and in full harmony with the others.Fire Pump Components:

- Engine (Driver): The engine is responsible for providing the power required to operate the pump. It can be an electric motor or a diesel engine, depending on the type of fire pump and its application. The engine drives the pump and supplies the mechanical energy needed to move water through the system.

- Pump: This is the main component that performs the actual water delivery. It converts mechanical energy from the engine into high-pressure hydraulic energy, enabling water to be pushed through the fire system to sprinklers, standpipes, or other required points.

- Strainer: The strainer protects the pump by filtering out debris or particles that may enter with the water supply. This prevents damage and ensures a smooth, uninterrupted water flow.

- Valve: Valves regulate the water flow from the pump to the distribution piping. They may be manual or automatic, depending on system requirements, and help maintain proper pressure and optimal water flow to the fire suppression systems.

- Gauge: Gauges monitor the water pressure within the system. They help verify that the pump is operating correctly and delivering the appropriate pressure needed for fire suppression.

- Pipes: Pipes are the channels that carry high-pressure water from the pump to the designated fire suppression areas. They serve as the connection between the pump and the rest of the fire protection system.

- Heat Exchanger: In some systems, a heat exchanger is used to maintain proper operating temperature for the pump, particularly in diesel-driven systems. It helps dissipate heat generated by the engine or high-pressure water.

How Does a Fire Pump Work?

- Activation: When a fire occurs, the system is activated either automatically or manually. The engine starts to operate the pump. Diesel fire pumps start through fuel ignition, while electric fire pumps activate instantly through electrical power.

- Water Suction: The pump begins drawing water from a source—such as a water tank or an external supply—through the suction inlet. Water passes through the strainer, which removes large impurities.

- Pressurization: After suction, the engine rotates the pump impeller, generating internal water pressure. This pressure forces the water through the system toward connected fire suppression components such as sprinklers or standpipes.

- Delivery to Piping: Once pressurized, water is discharged into the piping network and directed to sprinklers or other fire suppression outlets where it is used to control or extinguish the fire.

- Pressure & Flow Regulation: Specialized valves regulate system pressure and flow to ensure the required amount of water is delivered at the appropriate pressure for maximum fire-fighting effectiveness.

Why Is Installing Fire Pumps Important in Buildings in Saudi Arabia?

Fire pumps are a critical component of fire protection systems in buildings and facilities, especially in the Kingdom of Saudi Arabia, which continues to experience rapid growth in construction and urban development. With the increasing number of commercial and residential buildings, the need for effective fire suppression systems has become essential to ensure the safety of people and property. Here are the key reasons why installing fire pumps in buildings across Saudi Arabia is of great importance:- 1. Compliance with legal standards: Saudi regulations require the installation of fire pumps to meet local and international standards, helping building owners avoid penalties and ensure full legal compliance.

- Protection of lives and property: Fire pumps help extinguish fires quickly, minimizing damage and protecting occupants and valuable assets.

- Rapid emergency response: Fire pumps provide fast and efficient response during emergencies, significantly increasing the chances of controlling fires in their early stages.

- Keeping pace with urban development: As large-scale construction projects continue to expand across Saudi Arabia, fire pumps have become necessary to ensure the safety of major facilities.

- Reducing economic risks: Installing fire pumps reduces the financial impact of fires by enabling rapid control and minimizing repair costs.

- Building trust: Having fire pumps installed enhances trust and confidence among tenants and clients by providing an added sense of safety.

How Is a Fire Pump Calculated?

Calculating a fire pump is essential to ensure its effectiveness during an emergency. The pump capacity is determined based on several factors that define the required pump type, size, and water pressure needed to fully protect the facility. Here is a simplified explanation of how a fire pump is calculated:1. Calculating Water Flow Rate (Flow Rate)

The flow rate represents the amount of water that must be delivered within a specific time frame to suppress a fire effectively. The required flow rate depends on several factors such as the size of the facility, fire hazard classification, and the number of sprinkler heads or discharge points. Flow rate is typically determined based on local codes (such as NFPA 20) or Saudi Civil Defense requirements. In general, the calculation depends on:- The total building area (in square meters).

- The expected fire hazard classification.

- Sprinkler demand (number of sprinklers and the areas they cover).

2. Calculating Pressure

Pressure refers to the force required for the pump to deliver water through the piping network and to elevated levels such as upper floors. The required pressure is calculated based on:- Building height: Every additional meter in height requires extra pressure to push water upward.

- Piping length: Longer pipe runs increase friction loss, which requires additional pressure.

- Number of sprinklers: Each sprinkler head requires a minimum pressure to operate effectively.

3. Selecting the Pump Type

Once the required flow rate and pressure are determined, the pump type is selected based on:- Electric fire pumps or diesel fire pumps, depending on the site’s available power sources.

- Multi-stage pumps for applications requiring steady flow at high pressure.

4. Calculating Engine Power

Engine power is calculated based on the hydraulic energy needed to deliver the required water flow. The power is calculated using the following formula: P = (Q × H × ρ × g) / η Where:- P: Required engine power (in horsepower or kilowatts).

Q: Water flow rate (m³/h).

H: Total head or pressure requirement (meters). - ρ (rho): Water density.

- g: Acceleration due to gravity.

- η (eta): Pump efficiency.

5. System Testing

After defining all specifications, fire pumps are tested to ensure the system operates efficiently under all conditions. Testing includes running the pump at the required pressure for a specified duration to confirm reliable performance.

Fire Pump Installation Explained

Installing a fire pump is a sensitive process that requires precision to ensure the system can deliver water effectively during emergencies. Below are the essential steps that must be followed when installing fire pumps:1. Initial Planning

Before installation begins, the entire fire protection system must be carefully planned. This includes identifying the key points that require water supply (such as sprinklers, standpipes, or any fire suppression system). Water flow and required pressure are calculated based on local codes and technical recommendations.2. Selecting the Appropriate Location

A suitable location must be chosen for installing the fire pump. Typically, the pump is installed in a dedicated pump room or near the water source such as storage tanks. The location should be:- Dry and protected from moisture.

- Easily accessible for maintenance and testing.

- Away from areas exposed to high heat or potential damage.

3. Foundation Preparation

A fire pump requires a solid, level foundation to ensure stability during operation. Concrete bases are commonly used to support the weight of the pump and engine. The foundation must be strong enough to handle vibrations and load.4. Installing the Engine and Pump

After preparing the foundation, the engine (whether electric or diesel) is mounted and aligned with the pump. Proper matching of engine power and pump capacity is essential.- Electric motors are connected to the electrical supply.

- Diesel engines are connected to a fuel system and must be equipped with an adequate cooling system.

5. Connecting the Piping

The fire pump is connected to the building’s fire protection piping network. Pipes must be pressure-rated and durable enough to withstand high water pressure.- Pipes must be installed at correct angles to ensure smooth water flow.

- All fittings and pipes must comply with approved technical specifications.

6. Installing Control and Safety Valves

Control valves are installed to regulate water pressure and flow. These include:- Check valves to prevent backflow into the pump.

- Relief and safety valves to maintain optimal system pressure.

- Isolation valves to control water distribution to various system areas.

7. Setting Up Backup Power

Ensuring the availability of backup power is essential in case of a power outage. Electric fire pumps should be connected to a generator or backup battery system to ensure continuous operation during emergencies.8. Electrical Connections

For electrically driven pumps, the fire pump must be connected to the main power supply through dedicated electrical panels. Overcurrent and short-circuit protection systems must be installed. All wiring and switches must comply with local electrical safety codes.9. Testing and Commissioning

After installation is complete, a full system test must be conducted to ensure proper operation. Testing includes:- Verifying that the pump can deliver water at the required pressure.

- Testing the system to ensure water reaches all required outlets such as sprinklers.

- Inspecting safety components such as check valves and pressure control devices.

10. Routine Maintenance

Once the fire pump is installed and commissioned, a routine maintenance schedule must be followed to ensure continuous performance:- Regular inspection of pipes and control valves.

- Ensuring the engine functions properly.

- Cleaning strainers and periodic testing of backup power systems.

What Are the Main Types of Fire Pumps Available in Saudi Arabia?

1. Centrifugal Pumps (Horizontal Split Case Pumps)

- Description: One of the most common fire pump types, known for providing high flow and reliable pressure levels.

- Advantages: Easy to maintain due to its accessible split-case design, and features high operational efficiency.

- Applications: Used in large commercial and industrial facilities.

2. Vertical Turbine Pumps

- Description: Designed to draw water from deep sources such as wells or underground tanks.

- Advantages: Space-saving design, ideal for locations with limited installation area.

- Applications: Suitable for buildings that rely on below-grade or deep-water sources.

3. Electric Fire Pumps

- Description: Operate using electrical power and are the preferred choice when a stable electricity supply is available.

- Advantages: High efficiency, low operating cost, and quiet performance.

- Applications: Commonly used in residential, commercial, and medium-sized buildings.

4. Diesel Fire Pumps

- Description: Powered by diesel engines, making them ideal in case of power outages.

- Advantages: Provide an independent power source and serve as a reliable emergency backup.

- Applications: Used in industrial facilities and large buildings that require uninterrupted fire protection.

5. Jockey Pumps

- Description: Small-sized pumps used to maintain system pressure at all times.

- Advantages: Compensate for minor pressure drops and keep the system stable without triggering the main pump unnecessarily.

- Applications: Installed in all types of facilities as part of an integrated fire pump system.

At Arif Al-Nahdi Company (ANC), we supply top-quality fire pumps certified locally and internationally, ensuring full compliance with global safety standards. Whether you need electric pumps, diesel pumps, or centrifugal systems, we provide reliable and efficient solutions tailored to the unique needs of each facility, guaranteeing high performance and maximum reliability during emergencies.

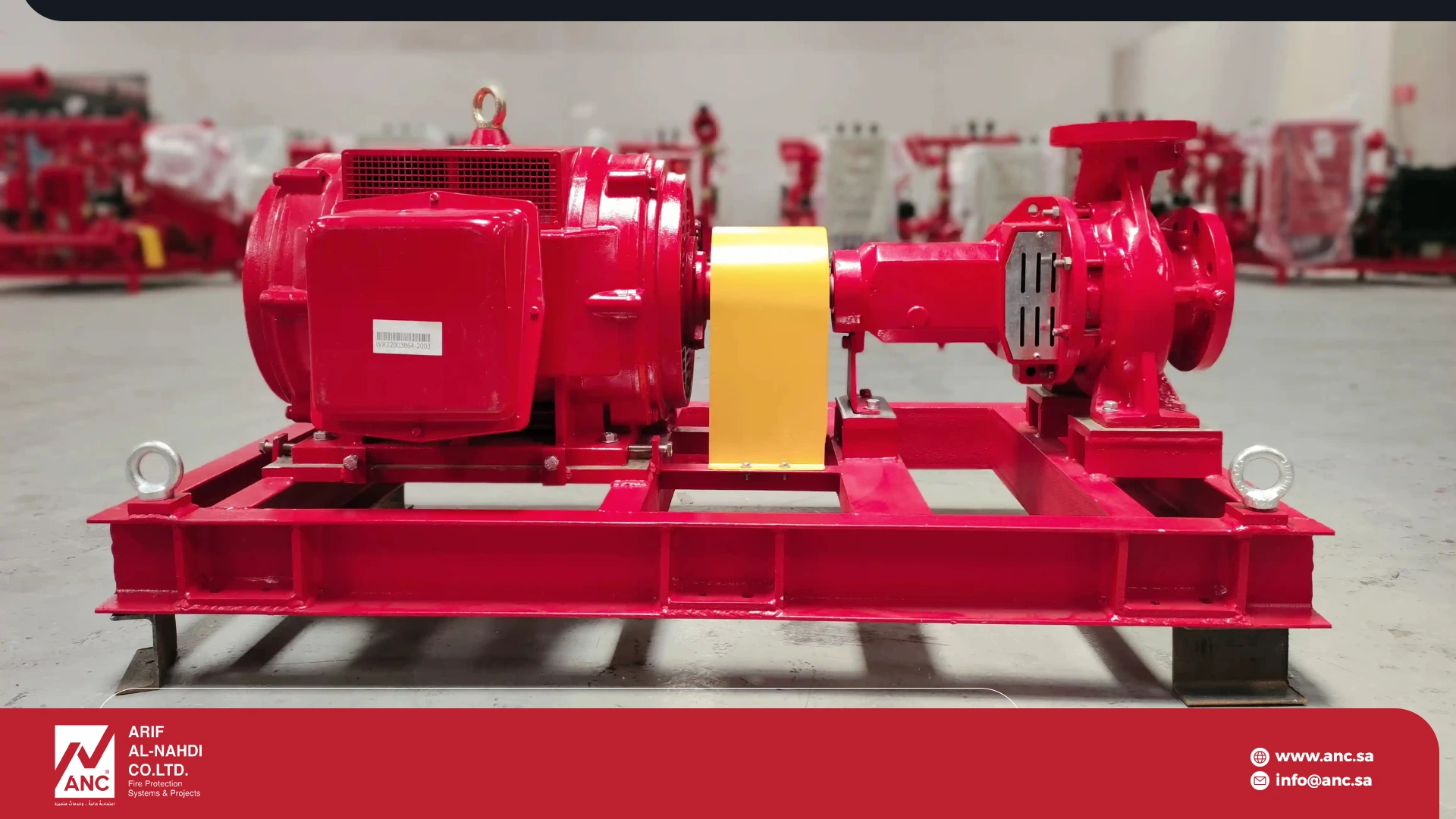

Fire Pump Types from Arif Al-Nahdi Company (ANC)

Arif Al-Nahdi Co. Ltd. (ANC) delivers advanced fire protection solutions through a range of high-performance hybrid fire pump systems. These pumps combine electric and diesel-driven engines in one integrated package to ensure uninterrupted operation and maximum reliability under all conditions.

The company offers three main hybrid fire pump models: E.D.J, E.J, and D.J.

- The E.D.J model features a primary electric fire pump, a backup diesel fire pump, and a vertical jockey pump to maintain system pressure.

- The E.J model includes a primary electric fire pump with a vertical jockey pump integrated within the same system.

- The D.J model includes a primary diesel-driven fire pump along with a vertical jockey pump for consistent pressure stabilization.

All units are pre-assembled on a single base frame (a Skid platform) and come equipped with all discharge-line accessories (control valves, pressure gauges) as well as a fully integrated automatic control panel. These systems are available in multiple flow capacities ranging from approximately 50 to 1500 GPM to meet various project needs.

All pump sets are certified according to international and local standards, ensuring safe and reliable performance that meets regulatory requirements.

Contact us today and let our experts help you choose the ideal model for your facility!

Key Advantages of High-Quality Fire Pumps from ANC

High-quality fire pumps offer a range of features that ensure exceptional performance and reliability during emergency situations. Here are the most important advantages:- Reliable Performance During Emergencies: Premium fire pumps deliver strong, continuous water flow at the required pressure, enabling fast and effective fire suppression.

- High Pressure Endurance: These pumps are engineered to withstand high operating pressures, making them ideal for high-rise buildings and large industrial facilities.

- Energy-Efficient Operation: High-quality fire pumps incorporate advanced technologies that reduce energy consumption while maintaining superior output—helping minimize operating costs.

- Easy Maintenance Design: Premium fire pump systems feature maintenance-friendly designs that simplify routine inspection and servicing, ensuring the pump remains ready for operation at all times.

- Long Service Life: Made from durable, high-grade materials, these pumps offer extended operational lifespan with minimal need for replacement.

- International Certification: High-quality fire pumps comply with globally recognized standards and local regulations, ensuring safety and optimal performance in all operating environments—making them the ideal choice for major facilities.

- Fast and Efficient Response: These pumps are designed to activate quickly and deliver immediate water pressure, helping reduce damage and protect lives during critical emergencies.

The Importance of Regular Fire Pump Maintenance

Regular maintenance of fire pumps is essential to ensure they remain fully operational and efficient during emergencies. Over time, fire pumps can be affected by various factors that may impact their performance, making routine maintenance crucial for preserving system reliability and preventing unexpected failures. Here are the key reasons why regular fire pump maintenance is so important:- Ensures effective performance during emergencies: Routine maintenance guarantees that fire pumps operate at full efficiency when a fire occurs. Neglecting maintenance can reduce pump performance, delay system response, and decrease the chances of controlling the fire quickly.

- Prevents unexpected breakdowns: Regular inspections help detect potential issues before they escalate. This includes checking the engine, piping, valves, and other components that may affect the performance of the entire system.

- Extends pump lifespan: Routine maintenance contributes to prolonging the life of the fire pump. Cleaning components and replacing worn-out parts keep the pump functioning efficiently for longer periods while minimizing costly repairs.

- Compliance with legal standards: Local and international regulations—such as those issued by Saudi Civil Defense and global fire safety standards—require scheduled maintenance of fire protection systems. Non-compliance can result in fines or legal liabilities.

- Improves energy efficiency: Maintaining fire pumps helps optimize energy consumption. Regular cleaning and leak detection can significantly reduce energy waste during operation.

- Detects leaks and mechanical friction: Some hidden issues, such as leaks or friction in moving parts, can severely impact pump performance. Regular maintenance ensures these problems are identified early and corrected before causing major damage.

- Ensures overall facility safety: A reliable fire suppression system is essential for the safety of any facility. With regular maintenance, you can ensure the system is always ready for operation, reducing risks and providing greater peace of mind.

Top Fire Pump Supply & Installation Companies in Saudi Arabia

Arif Al-Nahdi Co. Ltd. (ANC) is a leading manufacturer, supplier, and installer of the best fire pumps in the Kingdom of Saudi Arabia, delivering fully integrated solutions that meet the highest quality and safety standards.Why Choose Arif Al-Nahdi for Fire Pumps?

- Local and International Certifications: As a specialized fire pump company, ANC is the only company in the Kingdom with a registered brand certified by the Saudi Civil Defense, SASO, ISO, and NFPA.

- Advanced Local Manufacturing: Through its factory in Riyadh, ANC produces high-quality fire pumps built to international standards—supporting local industry and providing reliable products tailored to the Saudi market.

- Integrated Solutions: The company offers end-to-end services including design, supply, installation, maintenance, and testing—ensuring highly efficient execution of fire safety projects.

- Expertise & Professionalism: With a highly qualified engineering and technical team, ANC delivers innovative solutions that meet clients’ needs with top-tier professionalism—setting it apart from other fire pump companies in Saudi Arabia.

Fire Pump Prices in Saudi Arabia

Fire pump prices in the Kingdom of Saudi Arabia for 2025 vary based on several technical and operational factors. Understanding these factors is essential for determining the appropriate budget for your project.Key Factors Influencing Fire Pump Prices

- Pump Type: Electric fire pumps are suitable for buildings with a stable electrical supply. Diesel fire pumps are ideal when power outages are a concern, as they operate on fuel. Hybrid pump systems (Electric + Diesel + Jockey) combine the advantages of both for enhanced safety.

- Flow Capacity and Required Pressure: Prices vary based on the pump’s capacity (e.g., 250, 500, 1000 GPM) and required pressure (e.g., 7 bar, 10 bar).

- Specifications and Certifications: Pumps certified by organizations such as UL, FM, and NFPA 20 typically cost more but ensure superior safety and reliability.

- Engine Type: Diesel-driven fire pumps are more expensive than electric pumps due to stronger engines and higher operating and maintenance costs.

- Integrated Technologies: Systems with advanced control panels or automated monitoring features tend to have higher pricing.

- Project Location: Installation costs vary depending on location—major cities like Riyadh and Jeddah may have higher logistical and labor costs.

Frequently Asked Questions About Fire Pumps in Saudi Arabia

1- How does a fire pump work?

- A fire pump delivers water at high pressure to the fire suppression system, such as sprinklers or fire hose networks.

- The pump is activated either manually or automatically when a fire is detected.

- It relies on an electric motor or diesel engine to provide continuous and efficient water flow to the fire area.

2- What are the components of a fire pump?

- Engine (electric or diesel) that drives the pump.

- The pump itself, which delivers the water.

- Control valves to regulate water flow.

- Piping to distribute water throughout the system.

- Gauges and indicators to measure pressure and temperature.

3- How is a fire pump calculated and selected?

- Flow calculation: Based on the size of the facility and the number of sprinklers.

- Pressure calculation: Depends on building height and pipe length.

- Type selection: Choosing between an electric pump or a diesel pump depending on power availability.

- Selection standards: The pump should be certified according to standards such as NFPA and UL.

4- What is the typical pressure of a fire pump?

The required fire pump pressure depends on building height and pipe sizing. For high-rise buildings, discharge pressure is typically in the range of 7 to 10 bar.5- What are the best types of fire pumps?

- Centrifugal fire pumps (Horizontal Split Case Pumps) for large facilities.

- Vertical turbine pumps for deep water sources.

- Diesel fire pumps for locations prone to power outages.

- Electric fire pumps for buildings with a reliable power supply.

6- What is a Jockey Pump?

A Jockey Pump is a small-capacity pump used to maintain pressure within the fire system. It compensates for minor leaks and keeps system pressure stable without starting the main fire pump.7- What are the types of approved fire pumps?

- UL- and FM-approved centrifugal fire pumps.

- NFPA-compliant diesel fire pumps.

- Electric fire pumps certified according to local and international standards such as SASO and ISO.