In emergency situations, there is no room for error or delay—and this is where fire pumps play their role as a critical component of fire protection systems. They serve as the beating heart that pushes water through the network with speed and precision to protect lives and property.

But how do these systems operate with such accuracy? What components enable a fire pump to respond instantly when a fire breaks out?

In this article from Arif Al-Nahdi Company (ANC), you will learn how fire pumps work, their main components, how power is transferred from the driver to pressurized water flow, and the differences between electric, diesel, and hybrid pump systems.

Whether you are an engineer, a facility owner, or simply interested in safety systems, you will find here everything you need to understand how fire pumps remain in a constant state of readiness.

What Is a Fire Pump and What Is Its Purpose?

A fire pump is a centrifugal device used to increase the hydraulic pressure of water coming from a storage tank or a municipal supply, ensuring continuous flow that meets the fire suppression system requirements during emergencies.

Its main purpose is to deliver water at the designed pressure and flow rate to reach the farthest sprinkler or fire hydrant, despite losses caused by pipe length or elevation differences.

These pumps are used in residential, commercial, and industrial buildings and form an essential part of certified fire protection systems according to NFPA standards, thanks to their high reliability and immediate response when needed.

Key Components of a Fire Pump

A fire pump consists of several essential components that work together to ensure safe and efficient operation during emergencies. These include:- Impeller and Volute: The components responsible for creating centrifugal force to increase water pressure within the system.

- Driver (Motor/Engine): Can be either electric or diesel, and in some systems, a hybrid configuration combines both to ensure uninterrupted operation.

- Suction and Discharge Connections: Equipped with check valves and isolation valves to control water flow direction and prevent backflow.

- Instrumentation and Testing Devices: Such as pressure gauges, flow meters, and test points used to monitor system performance.

- Control Panel: Manages pump operation safely and sends fault alerts and warning notifications in case of performance issues.

- Jockey Pump: Maintains system pressure at the designed level and prevents frequent startup of the main fire pump.

- Mounting Base and Vibration Isolation: Provide stability during operation and reduce noise and vibration generated by the pump.

How Do Fire Pumps Work? (From Signal to Suppression)

Fire pumps operate within an integrated system that relies on sensing, automatic activation, and continuous control to deliver water at the required pressure the moment an emergency occurs. The process goes through several interconnected stages:1. Demand for Pressure

When a fire sprinkler or fire hose outlet is activated due to rising temperatures or manual intervention, a drop in the fire protection network pressure occurs. The jockey pump immediately detects this slight pressure drop and activates to compensate for minor leaks, helping maintain system pressure and preventing the main fire pump from running unnecessarily.2. Automatic Activation of the Main Pump

If the pressure continues to drop below the allowable threshold, the pressure switches or control panel send an immediate signal to start the main fire pump.- For an electric fire pump, the startup is almost instantaneous once the signal is received.

- A diesel fire pump, however, requires a brief startup period for the engine to ignite before pumping begins.

3. Pumping and Pressure Boosting

Once activated, the impeller inside the pump accelerates the water movement and converts kinetic energy into high hydraulic pressure. The pressurized water is then delivered through the piping network to reach the sprinklers, hose valves, or fire hoses with maximum force, in accordance with the system’s design specifications.4. Protection and Control

During operation, the control panel continuously monitors system performance through sensors and instruments.- Check valves prevent water backflow into the pump.

- Instrumentation monitors pressure and flow to ensure the pump operates within safe limits. Immediate alerts and warnings are issued in case of issues such as low suction pressure, engine overheating, or abnormal shutdown.

5. Safe Manual Shutdown

Once the emergency is over and the system pressure stabilizes, the pump is manually shut down from the control panel according to site procedures. The pump does not shut down automatically to avoid premature stopping before the fire is fully controlled.

What Are the Types of Fire Pumps?

Types of Fire Pumps Based on Operation/Construction

- End-Suction (widely used and easy to maintain).

- Split-Case (higher capacities and good efficiency).

- Vertical Turbine (ideal solution for underground tanks or wells).

Types of Fire Pumps Based on Installation

- Horizontal (common and easy to access).

- Vertical (space-saving for compact pump rooms).

Types of Fire Pumps Based on Power Source

- Electric (instant startup, low operating cost, minimal noise and emissions).

- Diesel Pumps (high independence and reliability during power outages).

- Hybrid Systems (Electric + Diesel) for facilities that cannot tolerate downtime.

- Jockey Pump for pressure stabilization and preventing frequent main pump starts.

How Is a Fire Pump Selected?

- Design flow rate (GPM/LPM) according to facility hazard level and network coverage (sprinklers/hydrants).

- Required pressure at the farthest point (calculated from elevation difference + friction losses + residual pressure).

- Available power source (stable electricity or the need for diesel independence).

- Installation environment and space (vertical/horizontal, pump room layout, ventilation, fuel tank if applicable).

- Integration with alarm systems, automatic operation, and central supervision.

- Certifications (SASO/UL/FM) and compliance with project specifications.

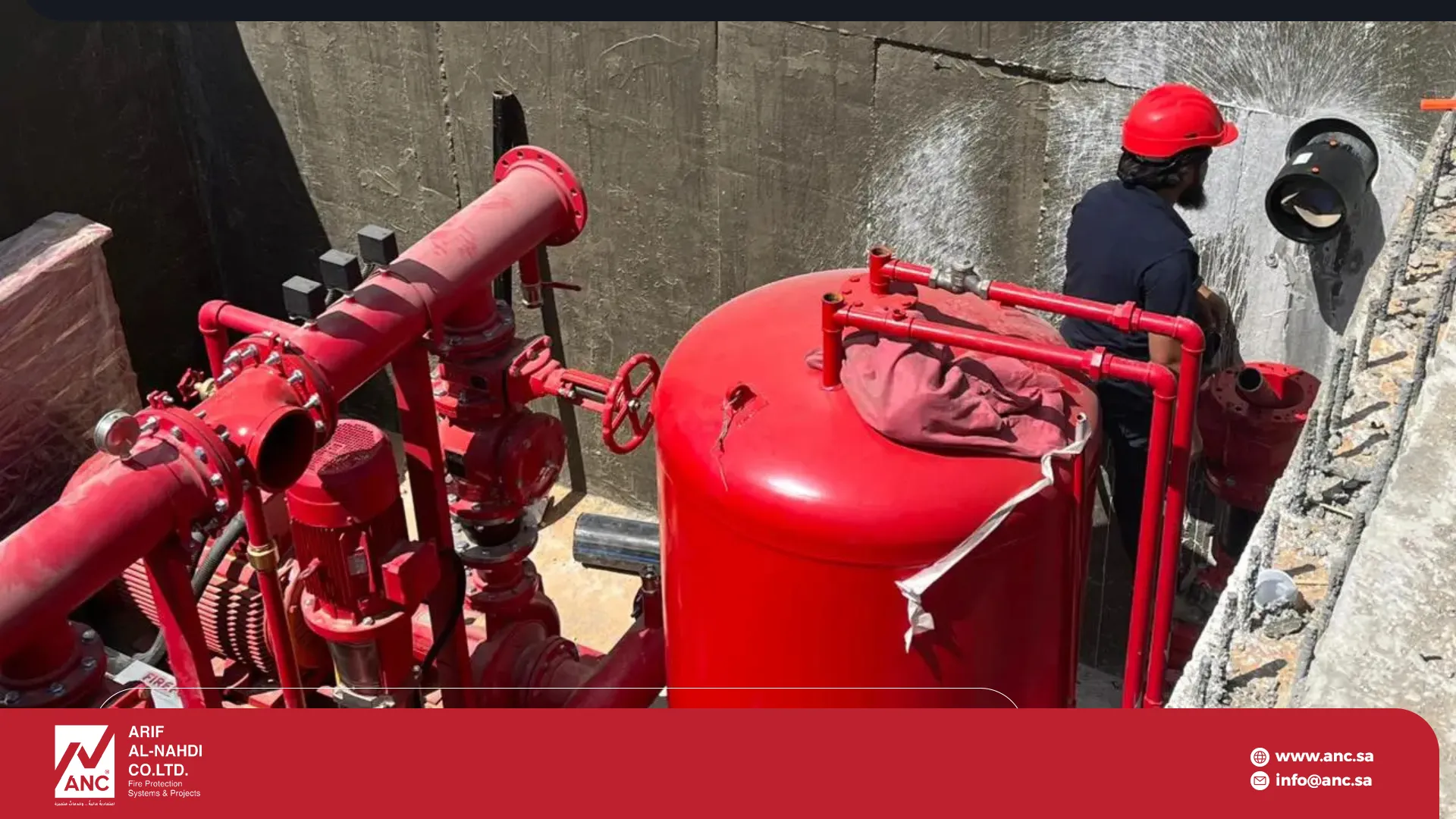

Fire Pump Installation – Key Success Factors

Proper installation of fire pumps is a critical factor in ensuring system efficiency and safety. Even the highest-performing pump may lose effectiveness if not installed accurately and in compliance with standards. Below are the essential points to ensure a successful installation:- Precise mechanical alignment between the driver and the pump to minimize vibration and ensure efficient power transmission.

- Proper sizing and velocity control of suction lines to avoid cavitation and maintain stable water flow.

- Installation of isolation and check valves in well-studied locations to facilitate maintenance and prevent hydraulic backflow.

- Provision of instrumentation and testing points such as pressure gauges, flow meters, and test connections to monitor performance and verify design values.

- Reliable electrical or fuel supply, with a backup generator when necessary, to ensure uninterrupted operation.

- Conducting a performance and acceptance test (Flow Test) and documenting all readings to verify compliance with NFPA 20 requirements.

Operation and Maintenance – What Ensures Reliability?

The reliability of fire pumps depends on implementing a consistent operation and maintenance plan that guarantees full system readiness at all times. The key practices include:- Performing routine testing of both the main fire pump and the jockey pump to verify response time and operational efficiency.

- Inspecting fluid levels and batteries (for diesel pumps), in addition to regularly checking filters and belts.

- Monitoring vibration, temperature, and abnormal noises during operation to detect any mechanical issues early.

- Applying a preventive maintenance plan with a clear schedule and keeping essential spare parts on hand to ensure rapid intervention when required.

- Training operators on safe startup and shutdown procedures according to manufacturer instructions and standards such as NFPA 25.

ANC Fire Pump Products & Services (Riyadh and All Regions of Saudi Arabia)

At Arif Al-Nahdi Company (ANC), we provide complete fire pump supply solutions along with full design and implementation of fire protection systems—from start to finish—supported by local and international certifications and full compliance with the needs of the Saudi market.What We Offer

- Electric Fire Pumps: Instant startup, low operating cost, minimal noise and emissions, and simplified maintenance.

- Diesel Fire Pumps (Diesel-driven pumps): High independence and reliable operation during power outages, ideal for factories and remote sites.

- Hybrid Systems (Electric + Diesel) with Jockey Pump: Maximum readiness and continuity for critical facilities such as hospitals and airports.

- Control panels and accessories, jockey pumps, test connections, valves, gauges, and everything required for a complete pump room setup.

- Fire pump catalogs and fire pump PDF files containing technical specifications, operation manuals, and maintenance guidelines.

Why Choose Us?

- SASO / UL / FM certifications and full compliance with Civil Defense requirements.

- Specialized engineering teams for fire pump installation, certified testing, and official approval procedures.

- Routine maintenance, rapid response, and original spare parts to ensure long-term system reliability.

- Strong expertise among the top fire pump companies in Saudi Arabia, with a proven reputation for delivering projects on time and to agreed quality standards.