Have you ever experienced a sudden shutdown of the fire pump during a system test or at a critical emergency moment? That brief failure could mean losing control of the fire within seconds, halting production, and possibly causing irreversible losses. Many industrial facilities discover too late that the cause of the failure was not the pump itself, but the lack of preventive maintenance or the use of non-original spare parts.

In this article, we review the most common fire pump problems and the reasons behind sudden shutdowns, and we explain the effective solutions that guarantee you stable performance and immediate response under all conditions.

Continue reading to discover how Arif Alnahdi Company (ANC) helps protect your facility from fire pump failures through certified installation, maintenance, and genuine spare-parts services in Saudi Arabia.

Types of Common Fire Pump Failures

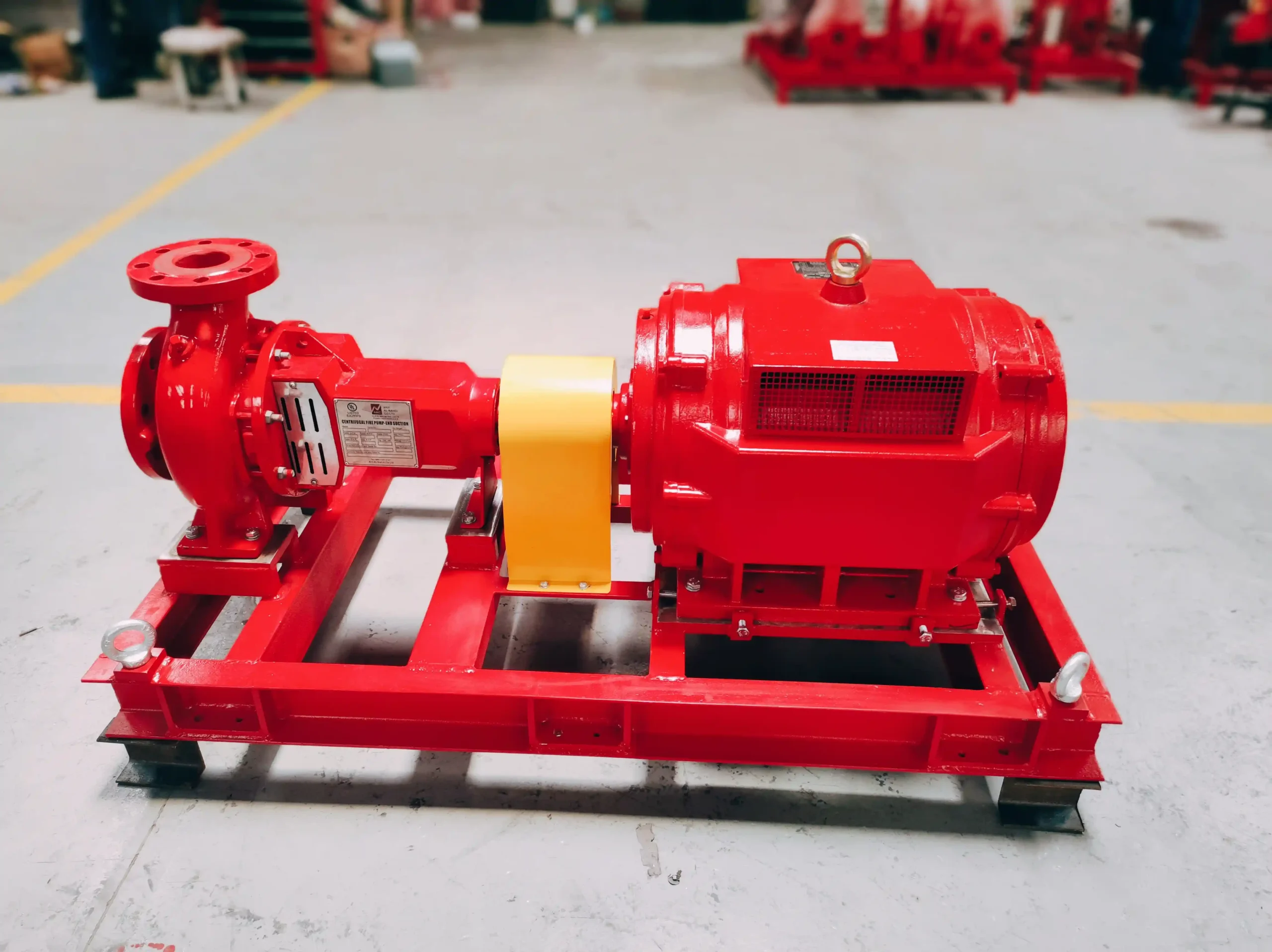

Industrial fire pumps are exposed to various types of failures due to continuous operation and harsh environmental conditions in industrial facilities. Understanding these failures helps detect them early before they cause the system to stop during an emergency. Here are the most common types of failures in fire protection systems:Mechanical Failures (Vibration, Impeller, Bearings)

These failures often occur due to mechanical imbalance or poor alignment between components, which leads to vibrations that affect pump efficiency. Over time, bearings may fail or the impeller may erode, causing pressure drops and a decline in the overall system performance.Electrical Failures (Control Panels, Cables, Motors)

Electrical issues are among the most common causes of pump breakdowns, especially in systems powered by electric motors. Poor insulation, damaged wiring, or faults in control panels may lead to a complete pump shutdown or failure in automatic start-up, exposing the facility to serious risks.Fuel System Failures (For Diesel Pumps)

In diesel fire pumps, fuel contamination or low fuel levels can cause the engine to stop suddenly during operation. Using unclean fuel or storing it for long periods leads to clogged filters and damaged injectors, preventing the pump from responding quickly during emergencies.Pressure and Flow Failures (Air Suction, Water Leaks)

Air entering the suction line or water leaking from connections results in noticeable pressure loss and reduced pumping efficiency. These failures may go unnoticed until performance tests or an actual fire occur, so pressure and flow systems require precise periodic inspection to ensure safe operation.Technical Causes of Sudden Fire Pump Shutdown

Sudden fire pump shutdowns often occur due to a simple technical fault that was not detected in time, yet it causes the entire suppression system to fail when needed. Since these pumps operate in harsh environments, any weakness in maintenance or performance monitoring can turn into a real hazard for the facility. Here are the most common technical causes behind sudden shutdowns:- Electrical Supply Issues: Power loss or voltage drops prevent the pump from starting or cause it to stop during operation.

- Blockage or Leakage in Suction Lines: Leads to pressure loss and reduced pumping efficiency due to air entering the system or water leaking from connections.

- Low or Contaminated Fuel (Diesel Pumps): Prevents continuous engine operation and may cause vibrations or sudden shutdown during use.

- Jockey Pump Failure to Maintain Pressure: Causes frequent and irregular operation of the main pump, reducing its lifespan.

- Bearing or Impeller Damage: Results in excessive friction, noise, and decreasing pump speed until it eventually stops.

- Failure in Automatic Start System: Prevents automatic response during pressure drops or fire events, putting the facility at risk due to delayed suppression.

Early Warning Signs Before a Fire Pump Fails

Fire pumps usually show several warning signs before a complete shutdown, and these indicators can be easily detected through regular system monitoring. Ignoring them may lead to sudden failure at the most critical moments.

Key early warning signs include:

- Unusual vibrations during operation

- Sudden increase in motor or bearing temperature

- Low water pressure or unstable flow

- Unusual noises or internal friction

- Fuel or water leakage from connection lines

- Frequent jockey pump activation without clear cause

- Delayed response from the control panel or fault indicators

- Rust or corrosion appearing on external pump components

- Burning smell or light smoke coming from the motor

Effective Solutions and Preventive Measures to Avoid Fire Pump Failure

Preventing failures in industrial fire pumps is essential to ensure the readiness of the fire protection system and protect both lives and property. By applying consistent maintenance, proper operation, and continuous monitoring practices, most causes of sudden pump shutdown can be avoided.

Preventive Maintenance for Fire Pumps

Following a regular preventive maintenance schedule ensures the system remains in optimal working condition. This includes inspecting pressure, cleaning filters, and lubricating bearings regularly. Such practices help detect issues early, extend the pump’s lifespan, and reduce emergency repair costs.

Proper Operation of Fire Pumps

Reliable performance begins with correct operation—during tests and emergencies. Technicians must be trained to operate the system according to manufacturer guidelines and ensure automatic start-up tests are conducted periodically. These steps prevent overload and guarantee immediate response when needed.

Genuine Spare Parts for Fire Pumps

Using genuine and certified spare parts ensures long-term performance and operational stability. Non-original components may cause mechanical imbalance or leaks in the hydraulic system. Arif Alnahdi Company (ANC) provides original spare parts and professional installation services for all certified fire pump types.

Smart Monitoring for Fire Pump Systems

Smart monitoring systems are the ideal solution for real-time fire pump performance tracking. Through sensors and connected control panels, early detection of pressure drops or rising temperatures becomes possible. This technology enables proactive maintenance and prevents sudden failures that may threaten facility safety.

The Role of Arif Alnahdi (ANC) in Fire Pump Maintenance & Operation

Arif Alnahdi Company (ANC) provides fully integrated solutions to ensure that fire pumps and fire protection systems operate with maximum efficiency and reliability across industrial and commercial facilities. We go beyond routine maintenance by offering complete technical support—from inspection to supply and installation.

Our services include:

- Preventive maintenance and scheduled operation of fire pumps according to NFPA and SASO standards.

- Performance checks and pressure testing to ensure system readiness at all times.

- Supply and installation of original, certified spare parts for all pump types.

- Upgrading outdated systems to comply with global UL/FM standards.

Protect your facility from unexpected failures with Arif Alnahdi (ANC)—your certified partner in fire protection systems in Saudi Arabia.

Contact us today to get a customized maintenance and operation plan tailored to your project needs.

Common Mistakes to Avoid After Maintenance

Although regular fire pump maintenance is essential, certain mistakes made after the maintenance process can cause new issues or reduce system reliability. To prevent such problems, be aware of the following errors:

- Not performing a test run after maintenance: This may lead to discovering faults too late when the pump is needed during real emergencies.

- Failing to reset the control panel: This can prevent automatic activation during pressure drops or fire incidents.

- Using non-compliant oils or lubricants: This may damage internal components or cause abnormal overheating.

- Leaving suction or discharge lines improperly sealed: This results in water leakage and pressure loss within the system.

- Lack of maintenance documentation: This makes it difficult to track previous issues and observations during future inspections.

Following correct post-maintenance procedures ensures that fire pumps remain fully operational, providing your facility with uninterrupted safety at all times.

FAQs About Common Fire Pump Problems

1. How do I maintain fire pumps?

Maintenance includes comprehensive periodic inspections such as operational testing, filter cleaning, bearing lubrication, pressure and flow checks, and verifying the control panel and automatic start system according to NFPA 25 standards.

2. What causes the pump to stop delivering water?

Common causes include suction line blockage, leakage in connections, low water level in the tank, or electrical faults preventing the motor from starting.

3. What is the most common cause of pump failure?

The most common cause is the absence of preventive maintenance, which leads to bearing damage, sediment buildup, or weak power supply—ultimately causing sudden pump shutdown.

4. How can I test fire pumps?

Testing is performed using a Flow Test to verify pressure and water flow, along with automatic and manual start tests to confirm readiness. All results must be documented according to NFPA 25 requirements.