Fire protection systems operate at peak efficiency only when preventive maintenance for fire pumps is performed regularly and according to approved standards. Neglecting inspections or delaying maintenance can lead to system failure at the most critical moment, putting lives and property at serious risk. This makes routine preventive maintenance and timely system upgrades essential to ensure continuous safety and compliance with the latest NFPA and SASO requirements.

In this article, we highlight the importance of preventive maintenance for fire pumps and answer the key question: When is it necessary to upgrade your fire protection system?

We also explain how Arif Al Nahdi (ANC) provides professional maintenance and comprehensive upgrade solutions that ensure reliable performance and full readiness of your fire protection system.

Continue reading to learn how to keep your fire protection system operating with maximum safety and efficiency.

What Is Preventive Maintenance for Fire Pumps?

Preventive maintenance for fire pumps is a planned program of inspections, testing, and routine servicing designed to keep fire pumps fully ready to operate according to design specifications and to reduce unexpected failures in fire protection systems.

These practices are based on NFPA 25, which serves as the primary reference standard for inspection, testing, and maintenance (ITM) of all water-based fire protection systems — including fire pumps — to ensure performance and reliability. Meanwhile, NFPA 20 defines the requirements for selecting and installing fire pumps so they operate exactly as designed during emergencies.

This approach includes scheduled visual and functional inspections, periodic performance testing, and corrective updates before faults escalate. It also follows product-certification standards such as UL 448 for centrifugal fire pumps.

The result is consistent pump efficiency, stable pressure, reduced downtime, and higher system reliability — especially in critical industrial and commercial environments.

How do we apply this at ANC?

We create a preventive maintenance plan aligned with the required inspection/testing cycles throughout the year and link it with clear performance logs to help you make early decisions regarding upgrades or replacement when needed, fully in compliance with NFPA 25 / NFPA 20 and relevant certification standards.

Types of Preventive Maintenance for Fire Pumps

At Arif Al Nahdi Company (ANC), we define preventive maintenance for fire pumps and fire systems as a scheduled inspection, testing, and servicing program that preserves readiness and prevents failures before they happen — fully aligned with NFPA 25 and installation requirements under NFPA 20.

- Weekly or monthly no-flow inspections and tests for fire pumps to ensure instant response during emergencies.

- Annual full-flow performance testing to verify the pump’s actual pressure–flow curve and overall hydraulic efficiency.

- Routine maintenance for diesel engines, batteries, and control connections according to NFPA 25 schedules and manufacturer instructions.

- Regular inspection of valves, suction sources, water tanks, and piping networks to ensure availability and remove obstructions before they cause failures.

- Documenting all inspection and testing results in official records, and managing temporary impairments through a structured action plan to reduce operational risk.

Note for Safety Managers:

When installing or upgrading UL 448 fire pumps, we first verify compliance with NFPA 20, then integrate the preventive maintenance program with NFPA 25 cycles to ensure year-round system readiness.

The Difference Between Preventive and Emergency Maintenance for Fire Pumps

Here is the practical difference we follow at Arif Al Nahdi Company (ANC) between preventive maintenance for fire pumps and systems and emergency maintenance, helping you choose the approach that preserves readiness and minimizes unplanned downtime.

| Item | Preventive Maintenance for Fire Pumps & Fire Systems | Emergency Maintenance for Fire Pumps & Fire Systems |

| Objective | Maintain system readiness through a scheduled Inspection / Testing / Maintenance (ITM) program to prevent failures before they occur. | Restore system operation after an unexpected failure or service interruption (Reactive/Breakdown). |

| Timing | Scheduled periodically (weekly / monthly / annually) based on system components and site requirements. | Unscheduled; performed when a failure impacts reliability or compliance. |

| Trigger | Compliance with reference standards (NFPA 25 for maintenance/testing, linked to proper installation per NFPA 20). | An incident, service outage, or pump/component failure alarm requiring urgent intervention to restore operation. |

| Scope of Work | Visual and functional inspections, test runs (with/without flow), annual full-flow test, diesel engine/control/battery maintenance, record-keeping, and impairment management. | Diagnosing the fault, repairing or replacing defective components, and possibly implementing temporary mitigation measures until completion. |

| Reference Standards | NFPA 25 as the main ITM standard, with optional guidance from FM Global preventive practices. | General safety guidelines and Emergency Action Plans (EAP) to protect personnel during emergency repair work. |

| Decision Indicators | Periodic test results, deviation from designed pressure-flow curve, inspection findings, aging of critical parts. | Failure alarms, sudden pressure drop, failure of pump start-up, or loss of performance. |

| Installation Requirements | Assumes installation compliant with NFPA 20 and use of certified components (e.g., UL 448 centrifugal fire pumps). | May reveal design/installation deficiencies that require corrective redesign after restoring operation. |

At Arif Al Nahdi Company (ANC), we prioritize preventive maintenance for fire pumps and fire systems through structured annual contracts that ensure year-round readiness and reliability in accordance with NFPA 20 and NFPA 25 — reducing unexpected failures across all facility types.

Key Preventive Maintenance Steps for Fire Pumps

At Arif Al Nahdi Company (ANC), preventive maintenance is a systematic process that begins with inspection and ends with documentation—ensuring maximum system readiness in full compliance with NFPA 20 and NFPA 25.

- Visual inspection of the fire pump to confirm absence of leaks, abnormal vibrations, and to verify mechanical/electrical connection integrity.

- Test-running the fire pump to confirm controller response, stable pressure, and proper flow performance during operation.

- Checking oil levels, lubrication, and motor-pump alignment to ensure smooth, efficient operation.

- Testing the jockey pump to verify its effectiveness in maintaining system pressure during normal standby conditions.

- Inspecting suction and discharge valves and supply lines to ensure proper movement and absence of blockages.

- Testing associated fire pump alarm and control systems, including manual and automatic start panels.

- Cleaning strainers and suction screens from sediment or obstructions that may impact pump performance.

- Documenting all inspection and testing results in periodic maintenance reports for future reference and follow-up.

With these routine steps, we ensure your fire pumps remain fully ready for operation at any moment and that your system stays compliant with Saudi Civil Defense requirements and international standards.

What Are the Preventive Maintenance Guidelines for Fire Pumps?

At Arif Al Nahdi Company (ANC), we follow preventive maintenance guidelines for fire pumps and fire systems as a practical framework that maintains readiness, ensures compliance, and reduces unexpected failures — all in line with NFPA 20, NFPA 25, and related certification requirements.- Follow the manufacturer’s manual along with NFPA 20 for installation and NFPA 25 for inspection, testing, and maintenance.

- Prepare a scheduled preventive maintenance plan with annual contracts covering the pump, its driver, and control systems.

- Perform test runs to verify response time, pressure stability, and flow rate within the approved design range.

- Check water sources, suction and discharge lines, and strainers to ensure availability and prevent blockages.

- Inspect isolation valves, check valves, and associated fittings to ensure correct movement and tight closure.

- Verify the integrity of control systems, alarms, manual/automatic control panels, and backup power sources.

- Calibrate gauges and instruments and maintain performance records, test logs, and technical reports for compliance and follow-up.

- Clean filters, lubricate mechanical points, and adjust alignment between the motor and pump when required.

- Check batteries and chargers, supply cables, and status indicators for diesel and electric systems.

- Document any temporary impairments and apply risk-reduction measures while notifying the responsible authority.

- Review equipment and service compliance with UL and SASO certifications as part of quality and system safety policy.

Why Is Preventive Maintenance for Fire Pumps Important?

At Arif Al Nahdi Company (ANC), we consider preventive maintenance a core part of fire system readiness and continuous protection across industrial and commercial facilities.- Reduce sudden failures by detecting and correcting issues early before they affect pump operation.

- Maintain pressure and flow performance within NFPA 20 design values and NFPA 25 test requirements.

- Extend the lifespan of mechanical/electrical assets and reduce unplanned replacement costs.

- Improve operational reliability and ensure proper response during alarms — protecting sensitive processes.

- Enhance compliance with local and international standards and periodic inspection requirements.

- Lower operational risks through documented maintenance records that support timely upgrade decisions.

- Support business continuity with maintenance plans aligned with your site’s operational environment.

When Should Fire Protection Systems Be Upgraded?

At Arif Al Nahdi Company (ANC), we recommend upgrading fire protection systems when preventive maintenance records or performance test reports show declining performance, or when:- There is a change in occupancy or hazard level (expansion, new production lines).

- There is non-compliance with local authority requirements (Civil Defense, SASO) or reference standards (NFPA 20 / NFPA 25).

- Failures recur frequently and repair costs increase.

- Equipment becomes outdated or spare parts are no longer available.

- Newer technologies can significantly improve reliability and emergency response.

How Does Upgrading Fire Protection Systems Improve Safety?

At Arif Al Nahdi Company (ANC), we consider upgrading fire protection systems a step that immediately enhances safety. Replacing outdated components with UL-certified, SASO-compliant parts — and aligning the system with NFPA 20/25 requirements — improves pump response, stabilizes pressure and flow during emergencies, and reduces recurring failure points.

Upgrades also make preventive maintenance more effective and enable more accurate control and alarm functions, helping safety teams make faster, more informed decisions. The result is a more reliable system, stronger compliance during inspections, and reduced operational costs over time.

The Role of Arif Al Nahdi (ANC) in Maintaining and Upgrading Fire Protection Systems

At Arif Al Nahdi (ANC), we provide integrated maintenance and upgrade solutions that keep your fire systems fully ready, highly reliable, and compliant with both local and international standards.

- Executing scheduled and annual maintenance contracts for fire systems and pumps, including electrical and diesel drivers and fire alarm components.

- Performing testing and commissioning through a qualified engineering team equipped with advanced diagnostic and programming tools.

- Delivering upgrade services that ensure full compliance with NFPA, SASO, and related certification requirements.

- Supplying and installing certified fire pumps, including UL-Listed Split Case and UL-Listed End Suction pumps for industrial and commercial sites.

- Supporting your projects across the Kingdom through our branches and specialized teams in installation, maintenance, and field follow-up.

For technical consultation or a maintenance/upgrade proposal, contact us — we’ll recommend the solution that best fits your site and compliance needs.

Which Fire Pumps Do We Offer at Arif Al Nahdi (ANC)?

At Arif Al Nahdi (ANC), we provide a full range of certified fire pumps designed for industrial and commercial facilities, meeting the highest local and international safety and quality standards.

Split Case Fire Pump — UL Approved

The Split Case pump from ANC is engineered for high-flow applications in factories, warehouses, and commercial facilities. Its axially split casing allows easy maintenance and high operational reliability. It features a double-suction impeller, lifetime-lubricated bearings, and optional mechanical seal or packing — all fully compliant with UL and NFPA requirements.

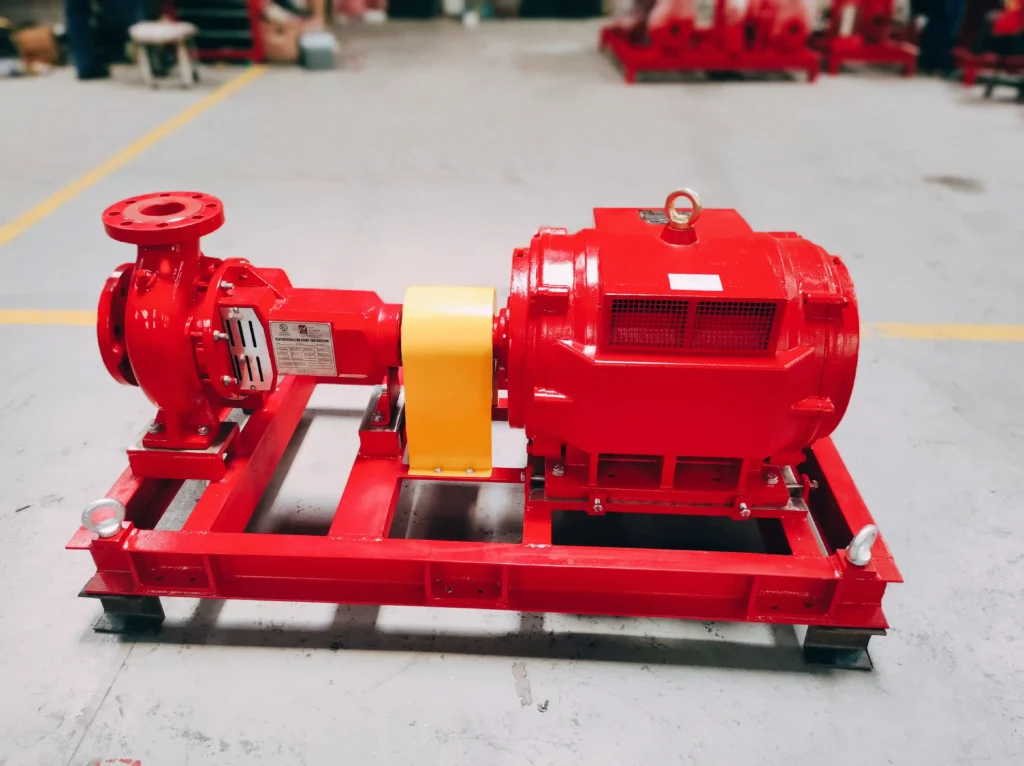

End Suction Fire Pump — UL Approved

ANC’s End Suction fire pump offers flexibility and efficiency, available in both electric and diesel versions. Designed according to NFPA 20, it provides stable performance with operating pressure within 90–140% of rated capacity. It is ideal for warehouses, commercial complexes, and multi-story buildings, and is UL-certified to ensure reliable and continuous protection.

D.J Fire Pump (Diesel + Jockey)

The D.J model combines a diesel engine with a jockey pump for immediate response during emergencies. Engineered for tough industrial environments, it offers high durability and strong performance. It is certified by SASO and fully compliant with NFPA and UL/FM standards.

E.D.J Fire Pump (Electric + Diesel + Jockey)

The E.D.J system provides a fully integrated solution combining an electric driver, a diesel backup driver, and a jockey pump for uninterrupted operation during emergencies. Its advanced design ensures high efficiency and flexibility for industrial and commercial projects, with full compliance to SASO, ISO, NFPA, and UL/FM certifications.

E.J Fire Pump (Electric + Jockey)

The E.J model includes a main electric fire pump supported by a jockey pump that maintains system pressure during normal conditions. With a compact design, easy installation, reliable performance, and official certifications including SASO, ISO 9001, and ISO 45001, it is an ideal choice for various facilities and buildings across Saudi Arabia.

Contact us now for a technical consultation and let us help you choose the most suitable fire pump for your facility — fully compliant with local and international standards.

Frequently Asked Questions About Preventive Maintenance for Fire Pumps

1. What are the steps for maintaining fire pumps?

Fire pump maintenance begins with a visual inspection of the pump and connections, followed by a test run to verify pressure and flow. This is followed by checking the valves and water source, cleaning strainers, lubricating moving parts, and documenting all results within the preventive maintenance plan in accordance with NFPA 25.

2. How is fire pump maintenance performed?

Maintenance is carried out according to a scheduled program that includes weekly no-flow test runs, full-flow annual testing, and inspection of the driver (engine), batteries, and control systems to ensure the pump is fully operational during emergencies.

3. How often should fire extinguishers be serviced?

Fire extinguishers are typically serviced every 6 to 12 months depending on the type and manufacturer’s recommendations, with a monthly visual check to verify gauge pressure, the safety pin, labeling, and overall condition of the cylinder.