In industrial environments—especially in Saudi Arabia, known for its high temperatures—machines operate continuously, and facilities often handle various materials that may be flammable. This makes the risk of fire a possibility at any time.

Neglecting routine maintenance of fire pumps in industrial facilities does not only lead to system failure; it can also result in severe losses in lives, property, and production downtime. Therefore, maintaining fire pumps in factories is not a routine procedure—it is an investment in operational safety and business continuity.

In this article, we explain the key reasons why regular fire pump maintenance is a necessity that must not be overlooked, and how a comprehensive maintenance program can preserve system efficiency and ensure compliance with NFPA and SASO standards in Saudi Arabia.

The Risks of Neglecting Fire Pump Maintenance

Neglecting fire pump maintenance in industrial facilities does not only lead to technical failures—it can also result in system malfunction during critical moments, putting lives and property at serious risk. Below are the most significant risks caused by the absence of regular maintenance:1. Pump Failure During Emergencies

If the pump is not regularly tested or inspected, it may fail to operate when needed during a fire, preventing the system from supplying water at the required pressure. This type of failure is among the most dangerous, as it renders the entire fire protection system ineffective at the moment it is most needed.2. Reduced Efficiency and Internal Component Damage

Sediment buildup, air in the suction lines, and cavitation can cause wear and erosion of the pump’s impeller, gradually reducing performance and lowering pumping efficiency. Neglecting filter cleaning and connection inspections also contributes to progressive system deterioration.3. Startup Delays in Diesel Fire Pumps

In diesel fire pumps, ignoring battery checks or fuel filter maintenance can lead to difficulty or delays when starting the engine during emergencies, causing critical delays in water delivery to the system.4. Increased Repair Costs and Operational Downtime

Failures caused by the lack of routine maintenance result in higher emergency repair costs compared to preventive maintenance. System breakdowns may also halt production in factories or disrupt operations in essential facilities, negatively affecting operational efficiency and productivity.5. Loss of Reliability and Non-Compliance with Safety Standards

Not following a regular maintenance program undermines confidence in system readiness and may lead to non-compliance with Civil Defense requirements and international standards such as NFPA and SASO, exposing the facility to penalties and legal consequences.

The Direct Benefits of Regular Fire Pump Maintenance

Regular maintenance of fire pumps is an essential part of ensuring facility safety and maintaining the efficiency of the fire protection system. The most notable benefits include:1. Ensuring Full Readiness During Emergencies

Routine maintenance ensures that the fire pump is ready to operate immediately when needed, without delays or malfunctions. Regular testing helps detect issues early—before they escalate during an actual fire incident.2. Extending the Pump’s Operational Life and Reducing Failures

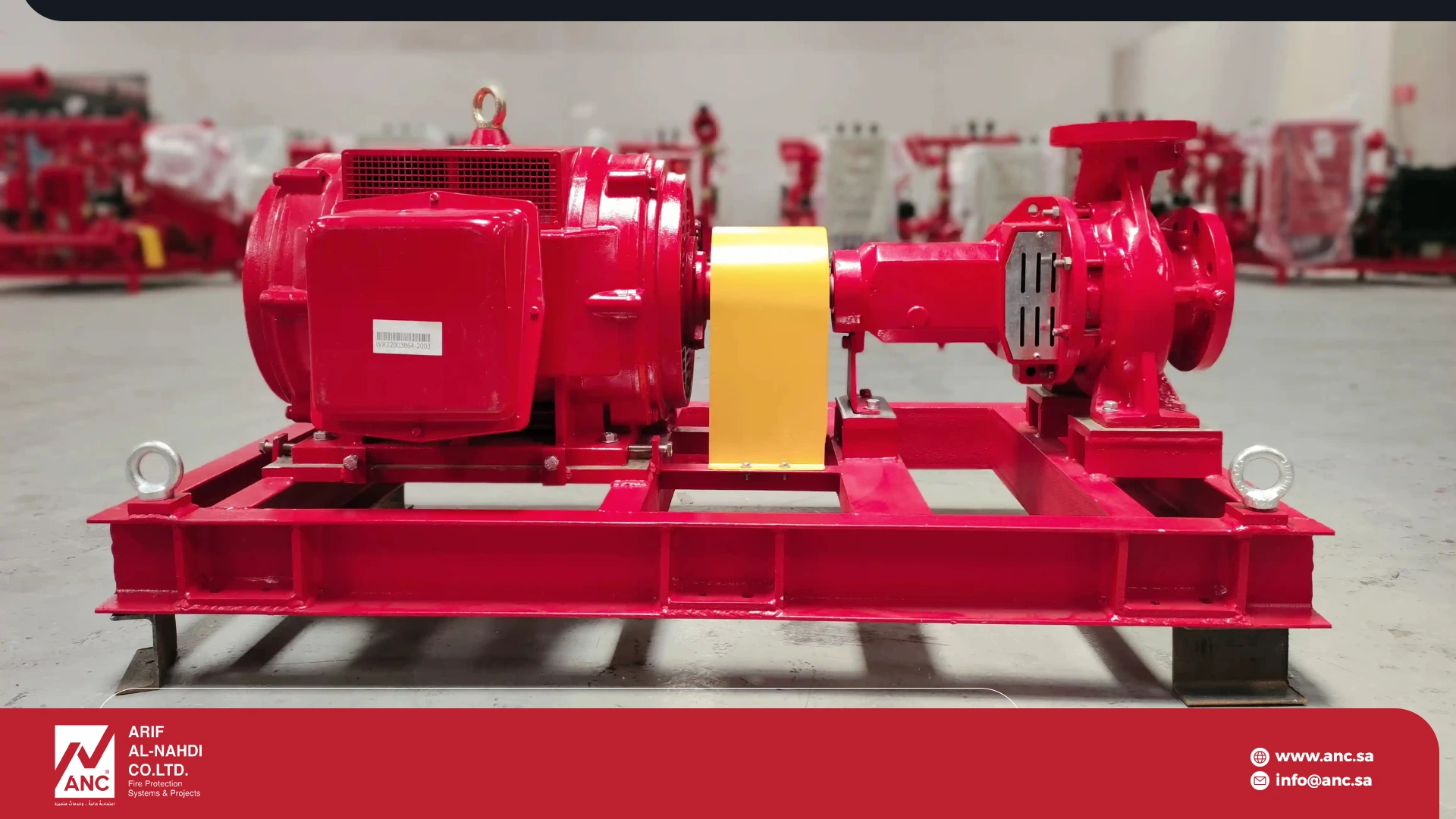

Through periodic cleaning, inspection of internal components, and replacement of worn-out parts, the mechanical performance of the pump is preserved, extending its operational lifespan. This helps reduce unexpected breakdowns and enhances system reliability.3. Lower Emergency Repair and Replacement Costs

Preventive maintenance is far more cost-effective than emergency repairs. Regular servicing prevents internal component deterioration and reduces the need for costly part replacements.4. Improved System Efficiency and Compliance with Performance Standards

When maintenance is carried out according to NFPA 25, the system delivers consistent performance and complies with Saudi Civil Defense requirements. Routine maintenance also improves energy efficiency and reduces fuel consumption in diesel fire pumps.

The Ideal Maintenance Program for Industrial Fire Pumps

Arif Al-Nahdi Company (ANC) recommends following a regular maintenance program aligned with both international and locally approved standards, which includes the following stages:1. Weekly Fire Pump Testing

A weekly operation test is conducted for the main fire pump and the jockey pump to verify system readiness and response speed when pressure drops.2. Monthly Fire Pump Inspection

This includes checking fuel, oil, and battery levels (for diesel pumps), ensuring the integrity of electrical connections, and reviewing pressure gauge readings.3. Quarterly Fire Pump Inspection

This inspection covers reviewing valves, control systems, and piping to detect any leaks or performance issues. It also includes reviewing previous test logs to evaluate overall system performance.4. Annual Fire Pump Maintenance

A comprehensive maintenance procedure is performed at least once per year in accordance with NFPA 25. This includes a full pump inspection, a flow test to verify design performance, and replacement of any damaged or worn components.

The Role of Arif Al-Nahdi Company (ANC) in Industrial Fire Pump Maintenance in Saudi Arabia

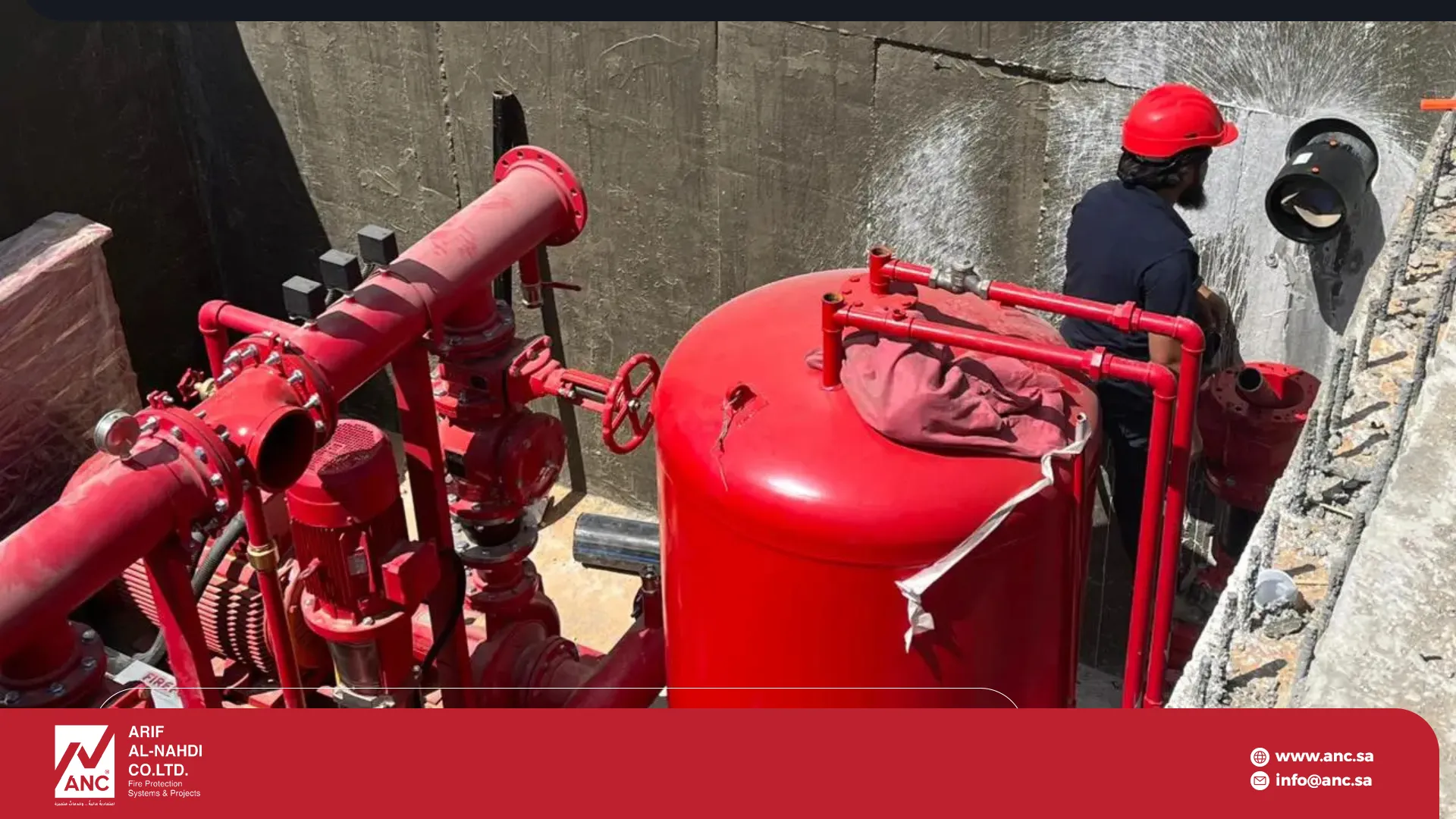

Arif Al-Nahdi Company (ANC) provides comprehensive maintenance solutions for fire pumps and fire protection systems in factories and major industrial facilities across Saudi Arabia, including:- Certified inspection, testing, and maintenance services in compliance with NFPA and SASO standards.

- Specialized technical teams trained to perform on-site testing with the highest accuracy and efficiency.

- Supply of original spare parts and UL/FM-certified fire pumps to ensure quality and long-term reliability.

- Flexible maintenance contracts tailored to different industrial facility sizes, with scheduled field visits.

Engineering Tips from ANC Experts to Ensure Operational Reliability

To achieve maximum operational efficiency and uninterrupted performance, the following recommendations are advised:- Use electronic maintenance schedules to track appointments and monitor periodic test results.

- Monitor vibration, pressure, and temperature levels regularly to detect early mechanical issues.

- Maintain a detailed record of tests and documentation to track pump performance and the maintenance history of each unit.

- Train operators and staff on safe startup, shutdown procedures, and emergency response plans to ensure readiness at all times.

Frequently Asked Questions About Fire Pump and Fire System Maintenance

1- What Are the Steps for Fire Pump Maintenance?

Fire pump maintenance is carried out through a set of structured steps that ensure full readiness during emergencies, including:- General inspection of connections and piping to ensure there are no leaks.

- Operational testing of the main fire pump and jockey pump to verify response.

- Checking discharge pressure and flow rate and comparing the readings with design values.

- Cleaning filters and ensuring suction lines are free of debris.

- Inspecting batteries and fuel levels in diesel fire pumps.

- Documenting all results in periodic reports according to NFPA 25 standards.